The Role of Chemical Pretreatment: Chemical pretreatment will involve the usage of chemical substances to wash the area, which promotes adhesion with the powder coating to adhere on slick or difficult metals. This process is typically completed utilizing a series of spray nozzles or an alkaline immersion dip.

The isocyanate team is normally introduced into your powder in blocked form where the isocyanate performance is pre-reacted with ε-caprolactame as blocking agent or in method of uretdiones, at elevated temperatures (deblocking temperature) the free of charge isocyanate teams are launched and available for the cross-linking response with hydroxyl performance.

This tough-carrying aspect also prolongs the floor coating’s helpful lifespan in contrast to standard paint. Powder coating levels is often thicker than paint given that they won’t sag or operate, including for their toughness.

Note that when different shades are blended and placed on exactly the same floor, the overspray may not be feasible for recycling due to the fact the color harmony is going to be incorrect.

A examine performed by Kolene Company highlighted that retaining a great floor in the powder application system considerably enhanced powder-coated surface topography.

If wikiHow has assisted you, remember to take into account a little contribution to help us in helping extra viewers such as you. We’re dedicated to offering the whole world with free how-to sources, as well as $1 assists us in our mission. Aid wikiHow Of course No Not Beneficial one Useful 0

This informative article is viewed 770,177 moments. Powder coating is a strategy of coating metal with a plastic complete applied in powder form and baked to some fluid condition to bond it to your metal area. Powder coating has a lot of positive aspects in excess of traditional liquid coating: It is really superior with the environment, applies thicker with no jogging, and is not difficult to design with.

This twin aim might be very challenging mainly because it calls for a stability involving innovative layout and realistic usability. For those las vegas powder coating involved with the look and improvement of recent merchandise (for example engineers and merchandise designers), it can be vital to concentrate on these features devoid of getting burdened via the complexities of the manufacturing course of action.

Ascertain the type of material you are likely to powdercoat and then select an appropriate powder to the complete. Powdercoating is completed with thermoplastic or thermoset polymer powder, and these products are formulated for bonding with unique foundation metals to present the ideal effects.

A latest improvement for that powder coating industry is using plasma pretreatment for heat-delicate plastics and composites. These components usually have very low-energy surfaces, are hydrophobic, and also have a very low degree of wetability which all negatively influence coating adhesion.

Powder coating is not simply realistic but will also environmentally friendly mainly because of the minimum unstable organic and natural compounds it releases. Unlike standard paints, powder coatings incorporate no solvents and so are preferable in industries in which environmental polices are stringent.

The affordability of polyester powder also can make it a value-efficient selection for both industrial and domestic makes use of.

For compact-scale Positions, "rattle can" spray paint is less expensive and sophisticated than powder coating. On the Expert scale, the capital price and time demanded for your powder coat gun, booth and oven are comparable to These for just a spray gun procedure.

Several spray nozzle configurations are available, Each and every suited to coating precise object styles. This variety permits specific coating techniques, minimizing waste and optimizing surface complete.

Scott Baio Then & Now!

Scott Baio Then & Now! Joseph Mazzello Then & Now!

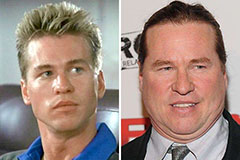

Joseph Mazzello Then & Now! Val Kilmer Then & Now!

Val Kilmer Then & Now! Dolly Parton Then & Now!

Dolly Parton Then & Now! Meadow Walker Then & Now!

Meadow Walker Then & Now!